High-performance solutions for sorting and recycling applications

Today’s sorting system technology is commonly used in the following industrial processing areas

- Food (fresh, dehydrated or frozen) such as nuts, grains, seafood, coffee, vegetables,

rice, corn, seeds, tomatoes, spices, tea, etc., in order to remove all impurities or defective products and meet the customer’s quality requirements.

to meet the customer’s quality requirements.

- Plastic product processing (PET, PVC, etc.) to ensure purity and protect production equipment from malfunctions.

Machinery, to prevent malfunctions.

- Chemical products. As the chemical industry is part of the supply chain of other industries

(food, pharmaceuticals, plastics, etc.), strict quality standards must be adhered to and sorting systems play an important role in ensuring product purity.

Sorting systems play a vital role in ensuring product purity.

- Pharmaceuticals such as tablets and pills must meet strict quality standard regulations

Strict quality assurance procedures must be followed at all stages of the entire production process.

Strict quality assurance procedures must be followed at all stages of the production process.

- Domestic and industrial/commercial waste recycling (glass, paper, ceramics, plastics, cardboard, metal, etc.), Cardboard, metal, etc.), where sorting systems play a key role in ensuring that recycled materials

The sorting system plays a key role in ensuring that recycled materials can be reprocessed in the corresponding production cycle.

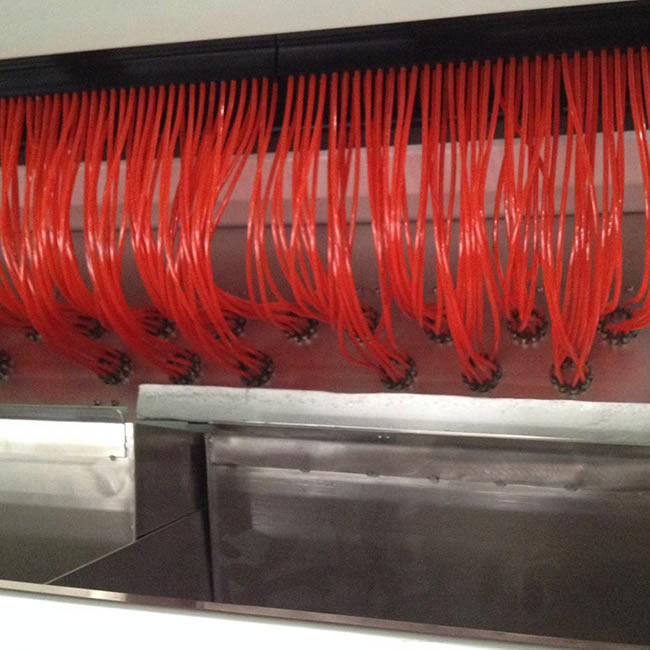

Matrix's mature technology is characterized by a highly innovative working principle, providing first-class performance, reliability and flexible solutions. No internal friction, reduced moving mass

The reduced moving mass and the use of energy-efficient materials enable extremely short response times, higher precision, better repeatability and lower power consumption.

At the same time, the modular structure integrates multiple shutters in a compact body.

At the same time, the modular structure integrates multiple shutters in a compact body, which greatly shortens the installation time and optimizes the overall design of the pneumatic system.

A wide range of ready-to-use products and the highest skills and technical knowledge

Focus on developing reliable specific solutions for customers in air ejection systems.

Features

- Compact dimensions and low weight

- Low power consumption values

- Short installation time

- Single or multi-channel configuration

- Open/close response time down to 1 ms (100% flow for precise and powerful ejection)

- Up to 500.000.000 cycles without performance loss (maintenance-free)

- Variable flow and configuration for increased flexibility

- 100% factory tested pre-assembled manifolds for up to 300 outlets

- Valve group outlet spacing from 6 mm

- Double manifold version (GMT) with adjustable vertical offset and minimum spacing of 3 mm